Robotic Integration Services

Custom Robotic Solutions for Manufacturing

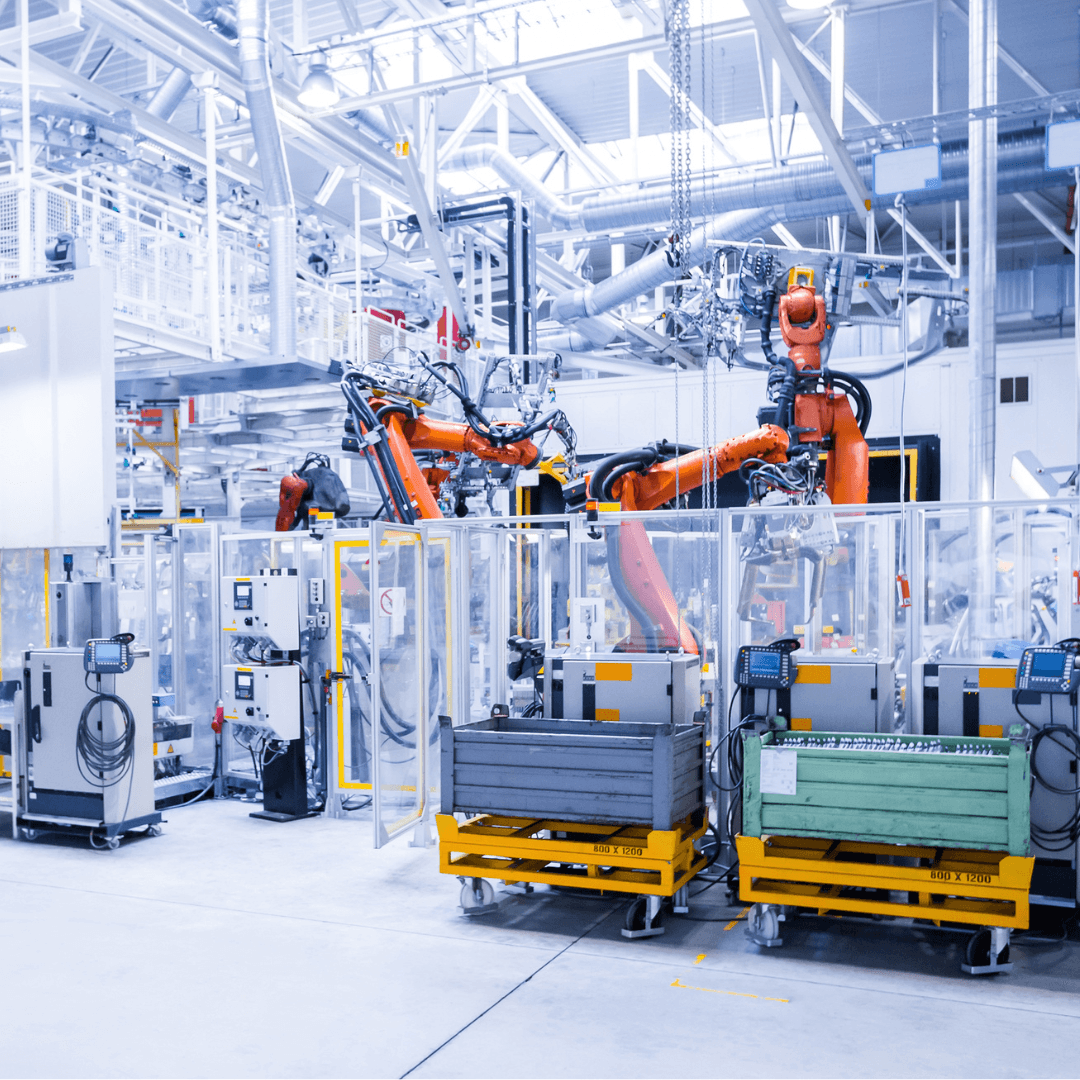

Robotic Applications

We design robotic systems that enhance your workforce - from heavy-duty industrial robots for demanding tasks to flexible cobots that collaborate directly with your operators. Our solutions adapt to your production needs while maintaining strict safety standards.

Industrial Power Meets Collaborative Flexibility

Our expertise spans the full spectrum of robotic automation:

- Industrial robots for high-speed, heavy-payload applications requiring absolute precision

- Collaborative robots (cobots) for flexible, human-interactive tasks that need adaptability

- Hybrid workcells where both technologies combine their strengths seamlessly

Tailored Automation Solutions

For material handling, we implement vision-guided systems that maintain throughput while reducing product damage. Our palletising solutions combine robotic strength with smart pattern generation to handle mixed loads efficiently. Welding cells feature both industrial precision and collaborative safety zones for optimal results.

Safety-Integrated Design

Every solution includes risk-assessed safeguards, whether it's full safety-rated stops for industrial robots or force-limited operation for cobots working alongside your team.

Our Robotic Integration Process

Application Analysis

Detailed workflow assessment and ROI evaluation

Concept Design

3D simulations and safety planning

Robot Selection

Optimal robot and tooling specification

Cell Integration

Full mechanical/electrical implementation

Validation

FAT/SAT testing with your team

Optimisation

Post deployment performance review

Ready to explore robotic automation for your facility?

Schedule AssessmentFrequently Asked Questions

Frequently Asked Questions

What's the typical payback period for robotic integration?

Most installations achieve ROI in 12-24 months through labour savings, quality improvements, and increased output.

Can your systems integrate with our existing PLCs?

Yes, we specialise in interfacing with PLC's including Siemens, Mitsubishi and other major brands.

How do you ensure safety in collaborative workspaces?

We implement risk assessments, programable safety controllers, and appropriate safeguards (light curtains, area scanners, or force-limited robots).

What maintenance do robotic systems require?

Typical maintenance includes annual mechanical inspection, periodic lubrication, and software updates - we can offer customised service plans.

Can you automate our legacy equipment?

Absolutely. We've successfully automated legacy machines with modern technologies and interface development.

Do you provide operator training?

Yes, comprehensive training covers operation, basic troubleshooting, and safety procedures tailored to your team's needs.

How does robotic welding compare to manual welding?

Robotic welding delivers 3-5x more consistent welds, 50% less rework, and can operate continuously without fatigue.